-

water level electrodes

-

Optical lens

-

quartz heating element

-

xenon flash tube

-

quartz glass plate

-

conductive glass

-

quartz glass crucible

-

quartz rod

-

quartz glass cuvette cell

-

GP20 Natrium lamp

-

quartz glass or labware product

-

magnetic stir bar

-

Garnet sand

-

tempered sight glass borosilicate glass

-

Optical lens

-

graphite crucible

-

quartz tube customized

-

Sensor

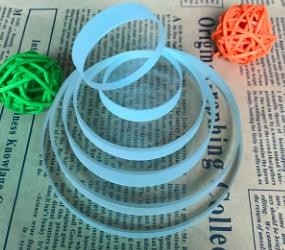

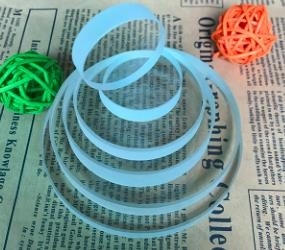

high temperature resistant 3.3 Borosilicate sight glass thickness 1mm and 30mm glass borosilicate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | 3.3 Borosilicate Glass | Feature | High Temperature Resistant |

|---|

Borosilicate glass or Pyrex glass

High borosilicate glass namely high temperature resistant glass, heat resistant glass, temperature differential glass.

The linear expansion coefficient is 3.3 + 0.1 × 10-6 K. it is a kind of glass based on sodium oxide (NA2O) , boron oxide (B2O2) and silicon dioxide oxide (SIO2) .

The content of borosilicate in the glass is high, boron: 12.5 ~ 13.5% , silicon: 78 ~ 80% , so it is called high borosilicate glass.

Properties of high borosilicate glass:

mechanical properties, compared with ordinary glass, high borosilicate 3.3 glass has the advantage of light weight, particularly suitable for applications with weight limitations (e.g. , Bulletproof glass) , density (25 ° C) , 2.2 g cm3 Young's modulus (25 ° C) , Siméon Denis Poisson ratio 480(ISO 9385) , bending strength

Coefficient of thermal expansion:

heat capacity 0.83 kj x (kg x k) -1 thermal conductivity, maximum operating temperature, short-term use of 500 ° C long-term use of 450 ° one-piece temperature difference (a glass to withstand the heating center and cooler edge temperature difference properties) thermal shock resistance (glass to withstand temperature sudden cooling properties)5mm160k borosilicate glass viscosity softening point 820 ° .

Chemical properties:

high borosilicate 3.3 glass contains very little ferrous ions and is therefore a clear, transparent, colorless glass. High borosilicate 3.3 glass is a kind of clear and transparent colorless glass. The excellent transmittance in the ultraviolet and visible near-infrared range makes the high borosilicate 3.3 glass an ideal material for many kinds of floodlights, high-power spotlights and sunbeds (operating temperatures up to 450 ° C) . High borosilicate 3.3 glass has low intrinsic fluorescence and good surface quality, which can be widely used in optics, optoelectronics, photonics and analytical equipment.

Due to its low alkali content, high borosilicate 3.3 glass can be used as a high insulator, so it is suitable for high temperature (up to 450 ° C) applications where materials with good non-conductive properties are required. Because of the unique structure of borosilicate glass, high borosilicate 3.3 glass has neutron absorption.

The basic guidelines for use and installation of glass and glass-ceramics also apply to high borosilicate 3.3 glasses.

1. In determining the dimensions of the frame and glass plate, the different thermal expansion rates between high borosilicate 3.3 glass and various frame materials, as well as possible tolerances in production, should be taken into account.

2. In the installation design, the glass needs to be pressed into the frame, the pressure must be evenly loaded on all sides of the plate, the pressure must be uniform.

high borosilicate glass can be further processed: 1, cutting 2, chamfering 3, chamfering 4, surface precision polishing 5, drilling 6, screen printing 7, sandblasting 8, hot bending

![]()

![]()